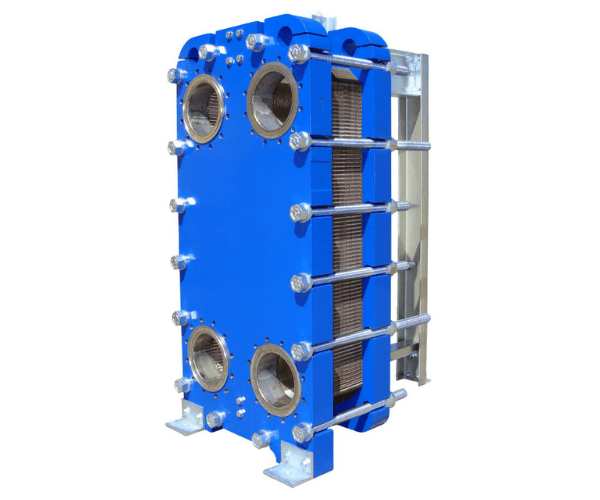

IPC can design, supply, engineer and fit most types of exchangers. We have various heat exchange products to suit different flow arrangements and needs of our customers. Our products are optimised to perform efficiently in the most demanding environments.

Our Full Range of Heat Exchangers Can Meet Any Bespoke Requirements.

With over 20 years experience designing, manufacturing, and installing a wide range of bespoke heat exchangers, IPC has become a trusted supplier of quality heat exchange and cooling products that meet the needs of commercial and industrial clients - providing reliable heating, cooling, and ventilation that runs efficiently and can be maintained effectively.

IPC's highly experienced engineers are established industry experts able to design and install a range of innovative industrial heat exchanger solutions, tailored to meet the different fluid flow arrangements and needs of any application for the transfer of heat. Our market-leading heating and cooling solutions are designed and optimised for the energy efficiency of any environment and to improve the cost-effectiveness of your business.

Learn more about the heat exchange solutions we can provide your business. Get in touch to talk with an expert.

Heat exchanger repair, cleaning and maintenance

Planned heat exchanger maintenance is essential for any type of heat exchanger. Ideally, routine maintenance and cleaning should be undertaken every 6 months, even if the heat exchanger appears to be functioning well it may not be running at its highest efficiency.

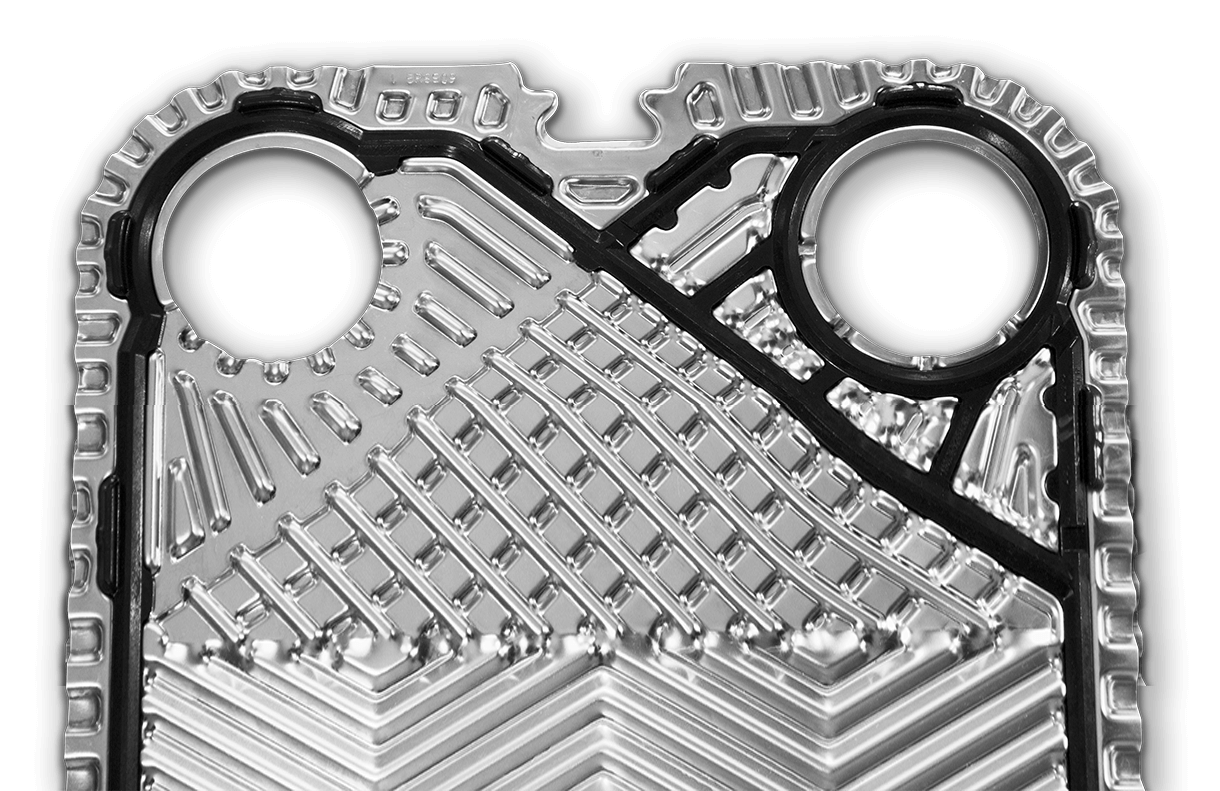

During our planned maintenance we will undertake a series of tests including pressure testing, a hydrostatic leakage test to confirm the internal and external sealing function of the heat exchanger, and crack dye penetration checking to locate any cracks, pinholes or failures. During plate heat exchanger maintenance we will also undertake any re-gasketing necessary, lubricate the tightening bolts with an extreme pressure grease, as well as the suspension wheels on the pressure plate and connection plates, ensuring to close the plate correctly to prevent any leaking or damage.

We also carry out any repairs you may need on your plate heat exchangers or shell and tube heat exchangers. The most common signs of a broken heat exchanger are the following:

- Increased pressure drop from inlet to outlet

- Reduced heat transfer efficiency

- Reduced flow and performance

- Leakage

If your exhaust gas heat exchanger is broken it is essential to get it repaired as quickly as possible to prevent harmful exhaust gases, including carbon monoxide, leaking into the air at work.

If your heat exchanger isn’t achieving the correct product temperatures for heating or cooling, it might be time to get it cleaned! We provide a full cleaning service to keep your heat exchanger performing like new, coming to the site and cleaning the shell with a high-powered water jet to get your exchanger back to its full efficiency.

Browse our range of heat exchanger products online, or if you’re interested in our bespoke plate, brazed or gas heat exchanger services simply get in touch with one of our professional engineers today! Give us a call on 0845 873 9916