Home | Products

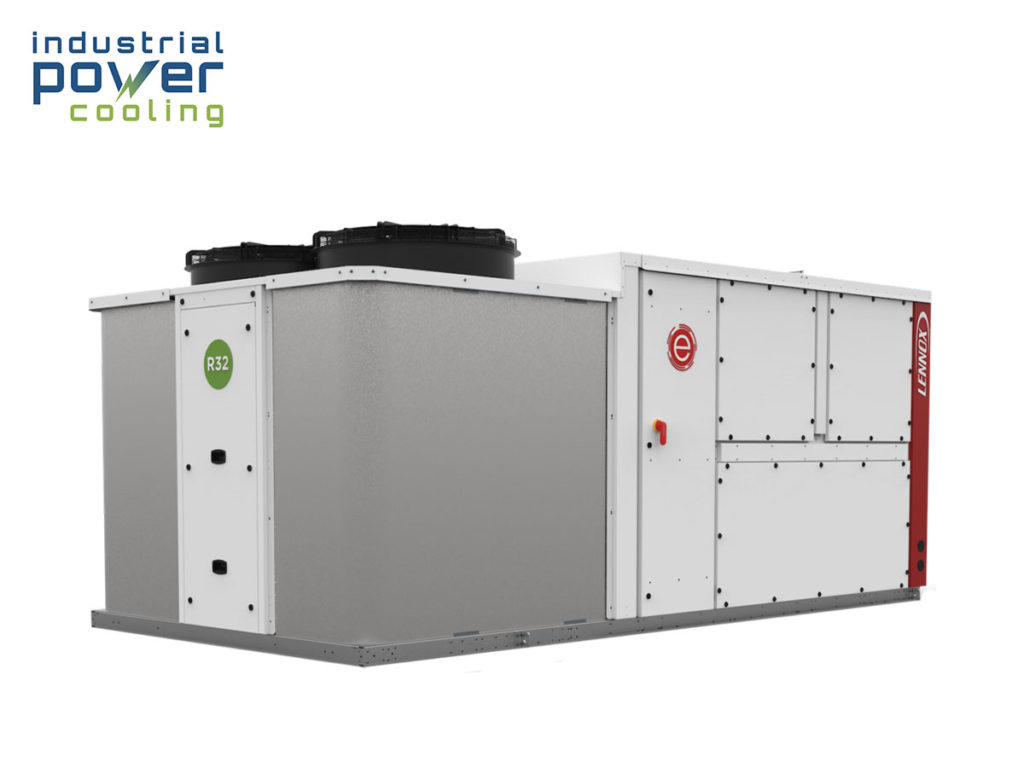

IPC chillers rely on refrigerant to output chilled air, suitable in ambient and working environments. Chillers can be used in most sectors and are used to cool beverage systems in hospitality, generators in power systems, MRI scanners, lasers, and more.

Our selection of chiller systems are designed to meet your cooling needs. With machines that can output well over 100kW, we can install a chiller solution right for you.

Keep your equipment cool in the heat of production with our complete packaged industrial chiller units

At IPC, we aim to tackle the challenges faced within the industrial sector, using a wide range of innovative and cost-effective solutions to deliver constant performance and improve operational efficiency. Our range of industrial chiller systems guarantee energy efficient and reliable cooling, efficiently drawing heat from equipment during the production process to prevent temperature spikes and minimise production downtime.

We believe in providing solutions that balance both supply and sustainability, our range of self-contained industrial chiller units and commercial chillers are capable of withstanding harsh environments, while delivering precision and reliability, keeping industrial, scientific or medical process equipment cool efficiently.

Customise your industrial chiller system with tailored solutions by the cooling experts

With over 20 years industry experience, and a catalogue of large-scale and international projects successfully operating, we have proven our ability to understand individual process requirements and provide a range of options to meet manufacturing needs. We are aware of the ever-increasing demands of providing industrial services to a growing population, and our versatile approach ensures a high quality and innovative system no matter the type of process application. We tailor our industrial chillers to meet your exact requirements, and our range supports future expansion, with the ability to cool 1-100+ pieces of equipment.

There are two types of coolers; air-cooled chillers and water-cooled chillers, both different in design. Air-cooled chillers absorb heat from the processed water and then send it into the air around the chiller unit. In comparison, water-cooled chillers use an external source of water to reject heat from a gaseous refrigerant in the condenser before it undergoes a phase change into a liquid.

A liquid refrigerant is used as part of the heat transfer process, which absorbs heat at a low temperature and low pressure and rejects heat at a higher temperature and a higher pressure. Both the water and air-cooled systems have a high energy efficiency rating, but water-cooled chillers are more energy efficient because they don't rely on an ambient dry-bulb temperature.

Our industrial chillers promise: