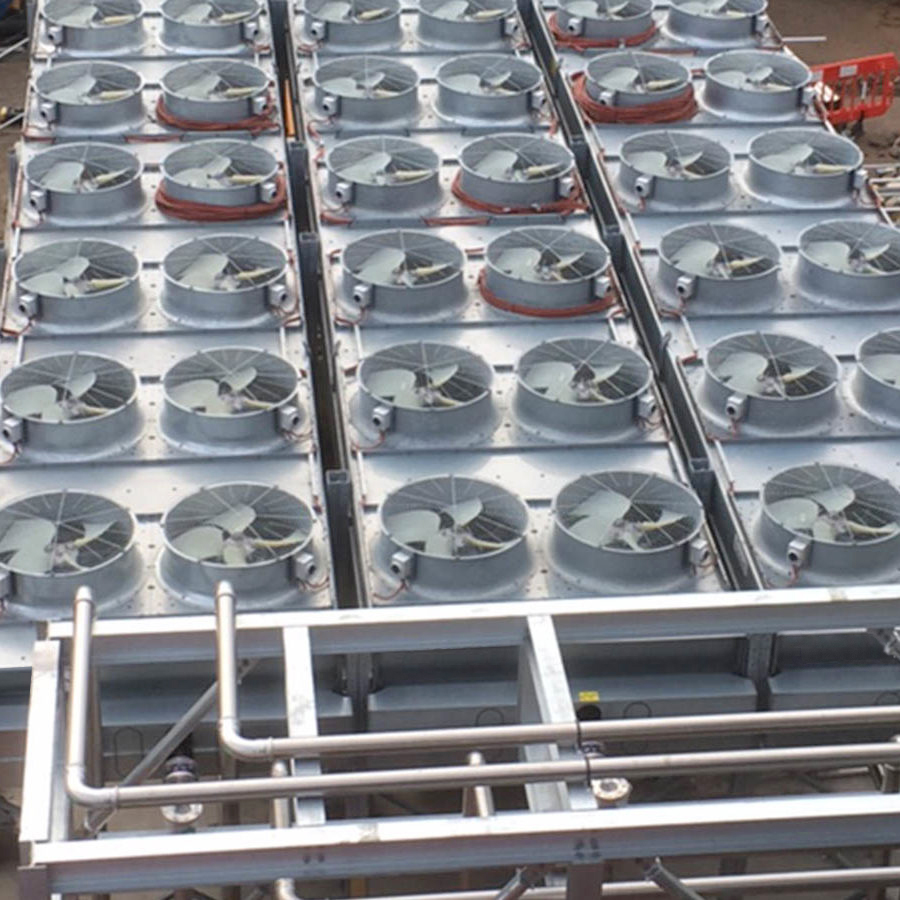

IPC specialise in the service and maintenance of heat exchanger systems across many industries.

Specialist Heat Exchanger Design & Installation

IPC’s highly experienced engineers are established industry experts able to design and install a range of innovative industrial heat exchanger solutions, tailored to meet the different flow arrangements and needs of any application. Our market-leading heating and cooling solutions are designed optimise the efficiency of any environment and improve the cost-effectiveness of your business.

Gasketed plate heat exchangers

Our gasketed plate heat exchangers are fitted with sheets of elastomeric gaskets, which provide a strong seal to prevent fluids from mixing or leaking while also creating channels through which fluid can be directed. The pack of plates are assembled between a frame plate and a pressure plate which is compressed by tightening bolts between the plates.

The design of the plate to plate heat exchanger means it can be easily dismantled for cleaning and maintenance by removing the bolts to separate the gaskets. It also makes repairing damages quicker and simpler as the broken gaskets can be removed and replaced without needing to replace any of the others. For this same reason, gasketed plate heat exchangers can also be easily adapted and expanded by adding or removing the plates, which changes the heating/cooling capacity for different operational conditions.

Due to its design, our gasketed heat exchanger is extremely durable and cost-efficient. The plates have a high resistance to corrosion and damage, along with the smooth plate surface and high turbulence which make the gaskets less likely to foul, this type of heat exchanger has lower maintenance and operating costs than other plate cooling and heating systems available.

Suitable for a range of applications involving heating and cooling, heat recovery, condensation and evaporation, our gasketed plate heat exchangers are ideal for heavy-duty applications such as district heating and cooling networks, HVAC, and even in industrial plants for waste heat recovery and pasteurisation.

Brazed heat exchangers

One of the most efficient and compact heat exchangers we offer are brazed plate heat exchangers. These plate exchangers are constructed from corrugated stacked plates with filler material between each plate, completely sealed together with fusion bonding for increased heat transfer.

As these brazed plate exchangers can be up to 90% smaller in both weight and size than gasket plate exchangers, these types of heat exchanger can be perfect oil and water cooling systems for smaller spaces. They’re also slightly more efficient than gasket exchangers thanks to the brazed surfaces creating a tighter, more effective seal.

This effective seal makes the exchanger more performance reliable, and better protects against the risk of leaks and pressure issues, saving you time and money which may otherwise be affected by a broken exchanger in the future. Our brazed heat exchangers have a versatile range of heating and cooling capabilities and can be customised to the specific requirements of your business.

Brazed plate heat exchangers are typically used in smaller applications, such as heat pumps, hot water tanks, transmission coolers, chillers and calorifiers, however in more recent years larger units have started to be manufactured for use in industrial applications and district heating installations.

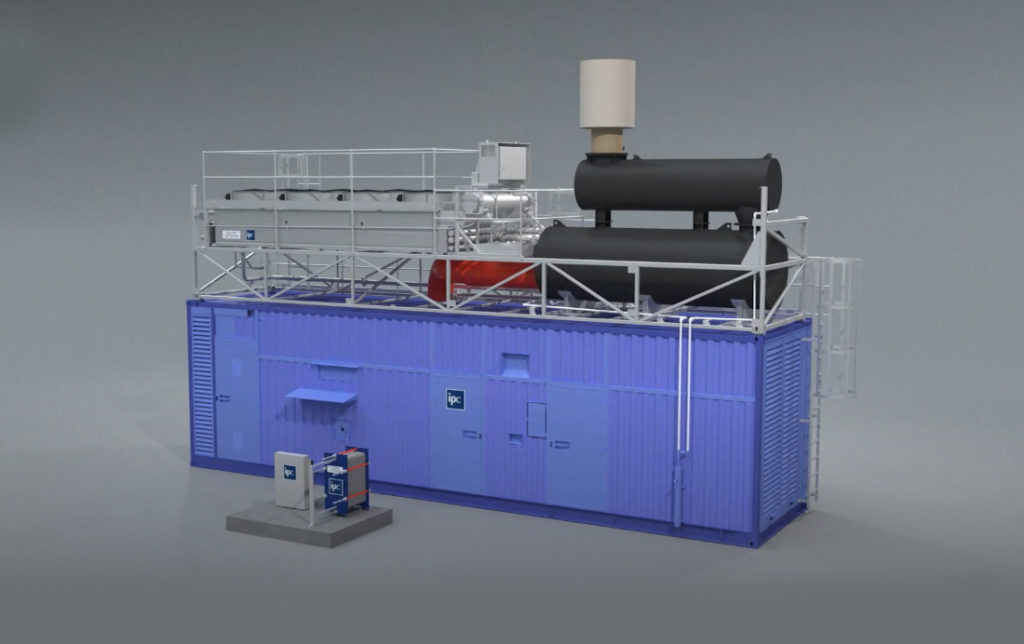

Exhaust gas heat exchangers

Our exhaust gas heat exchangers recover heat energy from the exhaust gases of reciprocating diesel, gas or biogas fuelled engines. This type of shell and tube heat exchanger allows heat generated by flue gases which would otherwise be wasted to be recovered and used to provide hot water or heat thermal oil in combined heat and power (CHP) systems.

Collecting waste energy and converting it into reusable heat can make your heat exchange system more efficient and environmentally friendly by lowering the amount of exhaust gas emissions released into the atmosphere. This effective solution can be installed wherever waste heat is generated by flue gases, including bakeries, hardening plants or plastic processing plants.

Heat exchanger repair, cleaning and maintenance

Planned heat exchanger maintenance is essential for any heat exchanger installation. Ideally, routine maintenance and cleaning should be undertaken every 6 months, even if the heat exchanger appears to be functioning well it may not be running at its highest efficiency.

During our planned maintenance we will undertake a series of tests including pressure testing, a hydrostatic leakage test to confirm the internal and external sealing function of the heat exchanger, and crack dye penetration checking to locate any cracks, pinholes or failures. During plate heat exchanger maintenance we will also undertake any re-gasketing necessary, lubricate the tightening bolts with an extreme pressure grease, as well as the suspension wheels on the pressure plate and connection plates, ensuring to close the plate correctly to prevent any leaking or damage.

We also carry out any repairs you may need on your plate heat exchangers or shell and tube heat exchangers. The most common signs of a broken heat exchanger are the following:

- Increased pressure drop from inlet to outlet

- Reduced heat transfer efficiency

- Reduced flow and performance

- Leakage

If your exhaust gas heat exchanger is broken it is essential to get it repaired as quickly as possible to prevent harmful exhaust gasses, including carbon monoxide, leaking into the air at work.

If your heat exchanger isn’t achieving the correct product temperatures for heating or cooling, it might be time to get it cleaned! We provide a full cleaning service to keep your heat exchanger performing like new, coming to the site and cleaning the shell with a high-powered water jet to get your exchanger back to its full efficiency.

Browse our range of heat exchanger products online, or if you’re interested in our bespoke plate, brazed or gas heat exchanger services simply get in touch with one of our professional engineers today! Give us a call on 0845 873 9916 or drop us an email at sales@ipcuk.com, and to you as soon as we can.